Drive solutions for every application

The increasing complexity of industrial plants means that the demands being placed on drive technology are also increasing. The angular gear units from ZAE have stood for the highest quality for many years. This applies both to our extensive catalogue pro-gramme and to tailor-made drive solutions that we develop entirely according to the specifications of our customers.

The phenomenon of self-locking relates to spindles and screw-type gear units such as worm gear units. What is important to know here is that not every worm gear is self-locking

For a self-locking or even self-braking gearing, certain conditions need to be fulfilled in the gearing geometry:

Self-locking:

- Inhibiting factor > 1

- Angle of central pitch for the gearing < 2.5°

Self-braking:

- Braking factor > 1

- Angle of central pitch for the gearing < 1.5°

In critical applications, such as for suspended loads, a self-locking or self-braking gearbox should not be used to replace a separate brake. In unfavourable cases, external influences, such as vibrations, can cause the self-locking to reverse. The following points are important in this context:

Static self-locking:

Self-locking means that a worm gear unit at rest can not be set to motion by applying torque on the wheel.

Dynamic self-locking:

Self-locking means that a worm gear unit at rest can not be set to motion by applying torque on the wheel. Here, the entire gear unit or even the output shaft alone can be exposed to sys-tem-induced vibration excitations.

Self-braking:

A gearbox is self-braking if, when the drive unit (motor) fails, internal friction alone causes it to slow down and come to a standstill, regardless of the load on the worm gear.

ATEX is the common abbreviation for "ATmosphères EXplosibles" (explosive atmospheres). In the past, corresponding guidelines were applied, mainly to electrical components. Flame-proof encapsulation and a type examination for use in potentially explosive atmospheres had to be certified for electric motors in particular. For several years now, the European Union has al-so laid down rules for using of mechanical components in explosive atmospheres. Different equipment protection levels (EPL) for equipment groups were defined for this purpose.

Type-examinations are required for the highest equipment protection levels. Manufacturers' risk assessments and declarations of conformity suffice for occasional explosive hazards. In this case, the type plate has to have the appropriate markings and the operating instructions have to draw attention to all potential hazards. ZAE Antriebssysteme offers its customers ap-propriate advice and products.

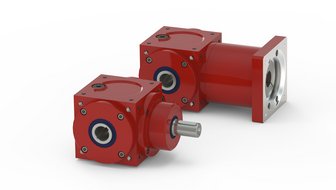

Choosing the right gear unit concept is critical to the power density, service life and efficiency of a drive train. Here, it is all about conserving resources and reducing total life-cycle costs. What is important is to find the right balance between all the requirements.

A good example of this is the successful optimisation of our bevel gear units. This develop-ment considered low-friction bearings and radial shaft seals and optimised lubricants. As a re-sult, power loss was halved and the performance of the drives increased significantly. We of-fer versions with reinforced gears and bearings for heavy-duty applications.

At ZAE, we pay close attention to efficiency and sustainability –> Blue Competence

Efficiency represents the ratio of delivered power to supplied power.

When it comes to efficiencies, it is important for us at ZAE to keep an eye on considerations concerning the whole powertrain (electrical and mechanical components). In addition to select-ing the right electric drive technology, on the transmission side, it is crucial to find a suitable concept as well. With respect to a gear unit, determining the gear types, gear stage number and ratio jumps are of crucial importance. The correct bearing and sealing concept and lubrication are also crucial.

Please note: There is no type of gear unit that is generally inefficient! The correct selection of the most suitable drive for an application is fundamental

Technical expertise in every phase of the process

The higher the requirements, the higher the demand for in-depth know-how and process quality. We accom-pany you from the initial conception stage, through construction and manufacturing, right up to assembly. So that your gear unit solution matches your needs perfectly.

Find out moreAt home in many industries

We know from experience: Specialist knowledge is indispensable in many areas of application so as to ensure that performance, operational safety and cost-effectiveness are optimally considered. Benefit from the suc-cess of our reference projects.

Find out more100 years of high-quality drive solutions

A common culture, eventful history and countless innovations over time weld us together as a team and allow us to deliver top performance. Get to know us and understand what drives us better.

Find out more

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/0/1/csm_produkte-servogetriebe-schneckengetriebe-z063-zae-getriebe_c542483574.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/1/csm_produkte-schneckengetriebe-zae-getriebe_1997fbc2ac.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/3/csm_produkte-getriebemotoren-stirnradschneckengetriebemotor-m100-zae-getriebe_74505be6a1.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/a/csm_produkte-radsatz-katalogradsatz-zae-getriebe_cf45183d38.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/5/csm_produkte-sondergetriebe-sonderkegelradgetriebe-zae_9e3ebe806a.jpg)